Fixture Maintenance & Repair Service

fixtureDOC:

Professional, fast & reliable

What would modern industry be without professional clamping technology and high-quality clamping elements mounted on a precision fixture? It’s only with their help that workpieces or tools can be securely and reliably held in place for further processing.

When fixtures fail or begin to show faults, it often leads to major disruptions in production workflows — and with that, significant financial losses. That’s why regular maintenance of clamping elements, CNC machines, and entire machining centers is essential. Prompt repairs when needed are just as important to keep your production running smoothly and your customers fully satisfied.

We are fixtureDOC, based in Böbingen an der Rems, and we specialize in the maintenance, repair, and servicing of fixtures. It’s our mission to ensure that your workpiece clamping systems remain fully operational — so you can always meet your customers’ expectations with confidence and reliability.

From Maintenance and Repairs

to Recommissioning

Whether it’s scheduled maintenance or an urgent repair – we’re your go-to partner for all services related to fixture construction and support!

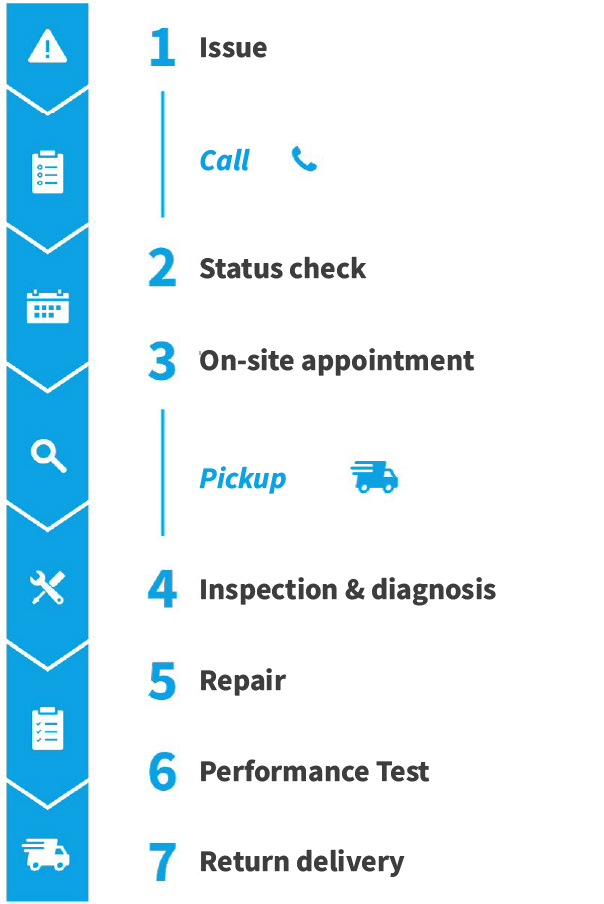

You can reach out to us via phone or email. Based on the information you provide, we’ll begin by narrowing down the issue and arranging an on-site inspection. During this visit, we’ll assess the situation and prepare the fixture for transport to our high-performance testing facility. At our site, we conduct thorough diagnostics to identify the root causes and resolve issues quickly – so your fixture is back in operation as soon as possible. Naturally, we’ll deliver your clamping fixtures promptly, allowing you to continue your production without unnecessary delays.

Below, you’ll find a detailed overview of our service process – so you can get a clear picture of the professional work we provide.

1. Issues with Your Fixture or Workpiece Clamping?

Don’t hesitate to get in touch! Call us at +49 7173 18594-0 or email us at doc@entzmann.de/en .

2. Get in Touch and Receive Comprehensive Consultation

During the initial phone consultation, we’ll take note of your concern and begin narrowing down the possible causes. With detailed descriptions, sketches, or diagrams provided by you, we’re often able to identify the issue with surprising accuracy, even before our on-site visit.

At Entzmann, we perform hydraulic, pneumatic, electrical, dimensional, and mechanical maintenance—no exceptions. And of course, the make or manufacturer of your machinery or fixture doesn’t matter to us. We service all systems, regardless of origin.

3. On-Site Appointment at Your Facility

During our first on-site visit, we’ll thoroughly assess the issue and plan the next steps together. Minor issues can often be resolved directly on location. For more complex problems, we dismantle the fixture and transport it via service vehicle to our testing facility in Böbingen, where it will undergo a comprehensive inspection and be fully restored.

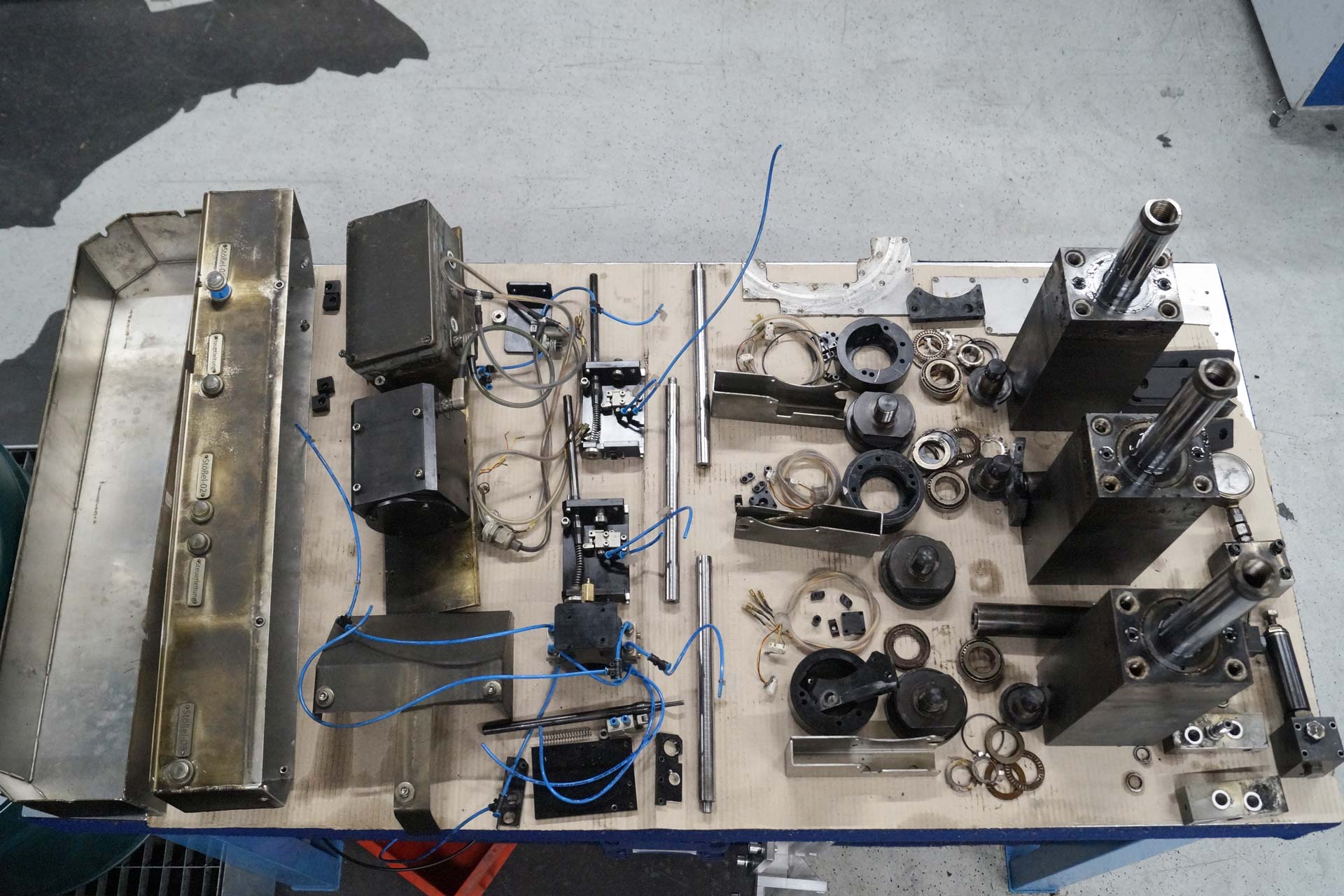

4. In-Depth Diagnostics in Böbingen

Your fixture will go through several stages of testing, including endurance runs, functional checks, and a detailed inspection of all components for damage or cracks. A final quality control round ensures all systems function flawlessly.

Based on this extensive testing, we generate a diagnostic report outlining the root causes and recommended repairs. You’ll receive this report to review the identified issues and proposed solutions.

5. Expert Repairs and Professional Servicing

All repairs are based strictly on the findings in your approved diagnostic report. If any unexpected issues arise, we’ll inform you immediately and agree on the next steps together.

Before repairs begin, your fixture is cleaned and reset. Upon your approval, all seals, screws, and valves are replaced, and damaged components are exchanged. The fixture is fully tested before being returned to you, ensuring flawless functionality.

6. Final Testing on Our High-Performance Test Bench

Each fixture is subjected to thorough testing after repairs, going above and beyond industry standards.

Our high-performance test bench is calibrated precisely to match your machine’s specifications (number of lines, line configuration, clamping pressure, and flow rate)*. In other words, your fixture is tested under realistic conditions, mirroring the setup of your CNC machine or machining center.

Here’s what our comprehensive quality and functionality testing includes:

- Individual function testing of every component

- Endurance testing with 500 to 1,000 clamping cycles*

- Pressure and holding tests for all clamping elements

- Final inspection of each individual unit

- Detailed documentation of the test results and performance data

7. Back to Peak Performance with Your Refurbished Fixture

Depending on the scope of the repair, your fixture will be delivered either directly by an entzmann specialist or via a trusted logistics partner. Repair costs are based solely on the actual time required and the parts replaced, transparent and fair. As an experienced tooling and machine builder, we offer a 12-month warranty on all repair work performed and on the individual replacement parts used. You can count on quality that lasts.

Take advantage of our all-in-one professional service: From the initial consultation, pickup and repair execution, all the way to delivery and on-site commissioning support, we provide you with a comprehensive and truly reliable service for all aspects of fixture construction and clamping elements. Everything from a single source, everything you can count on.