Clamping Fixtures, Custom-Made by entzmann

Looking for reliable, solution-driven clamping fixtures for your CNC machine? Then take the leap to the top with us!

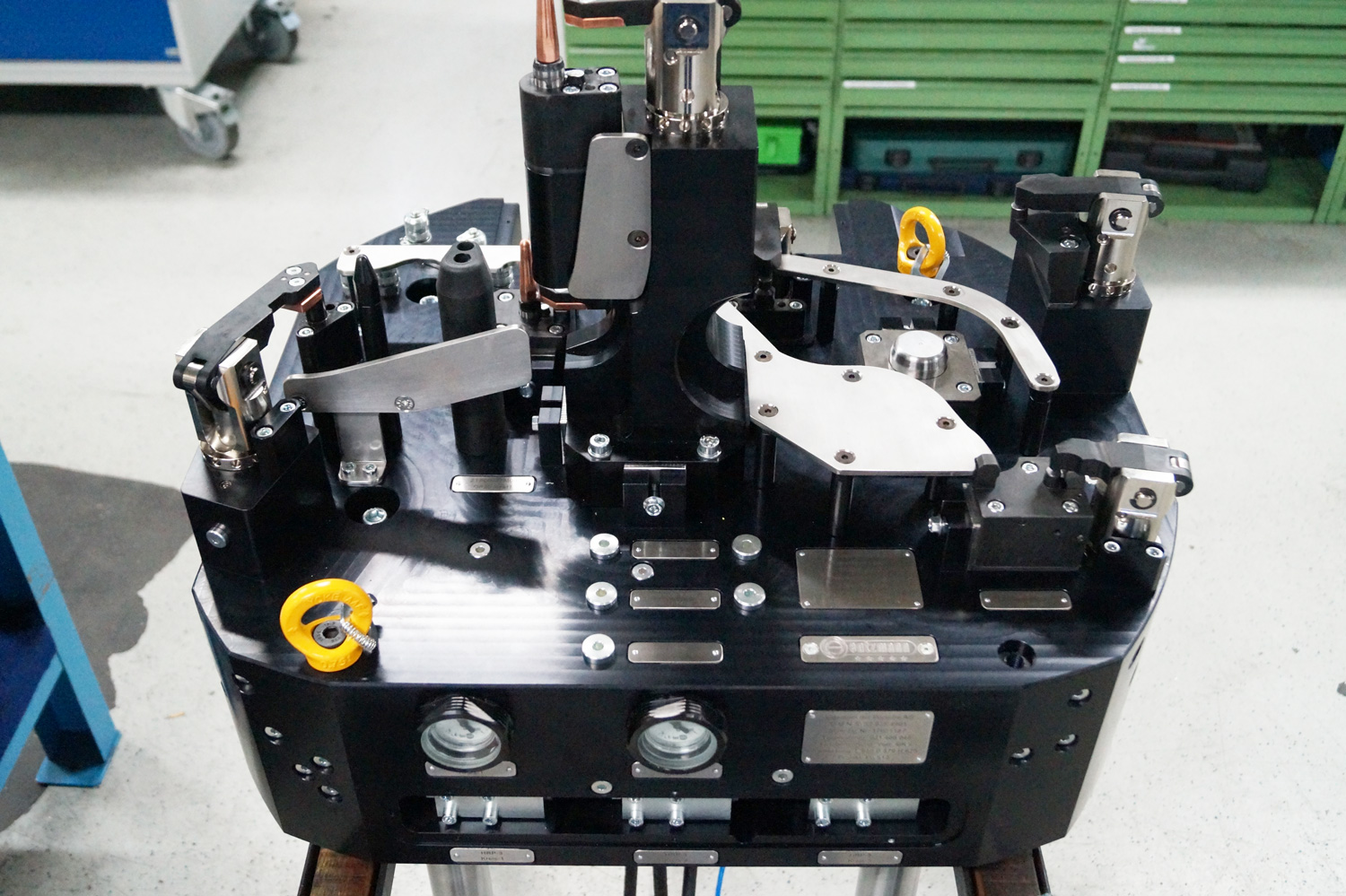

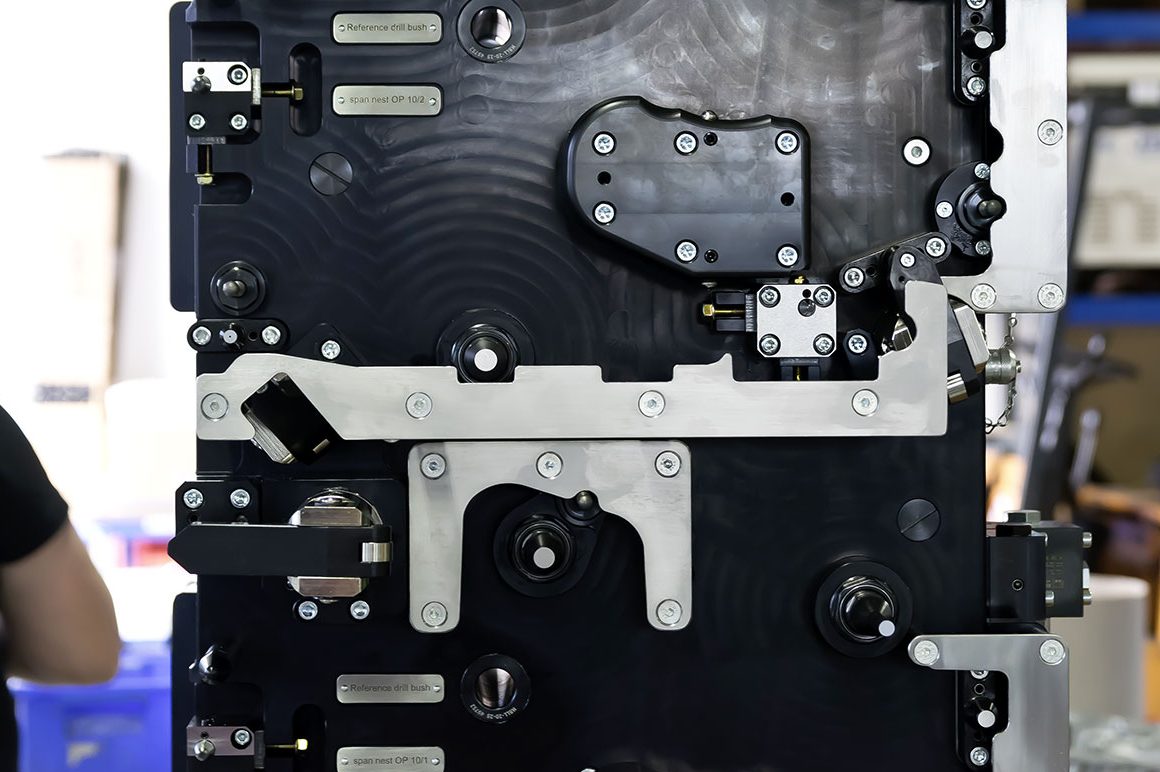

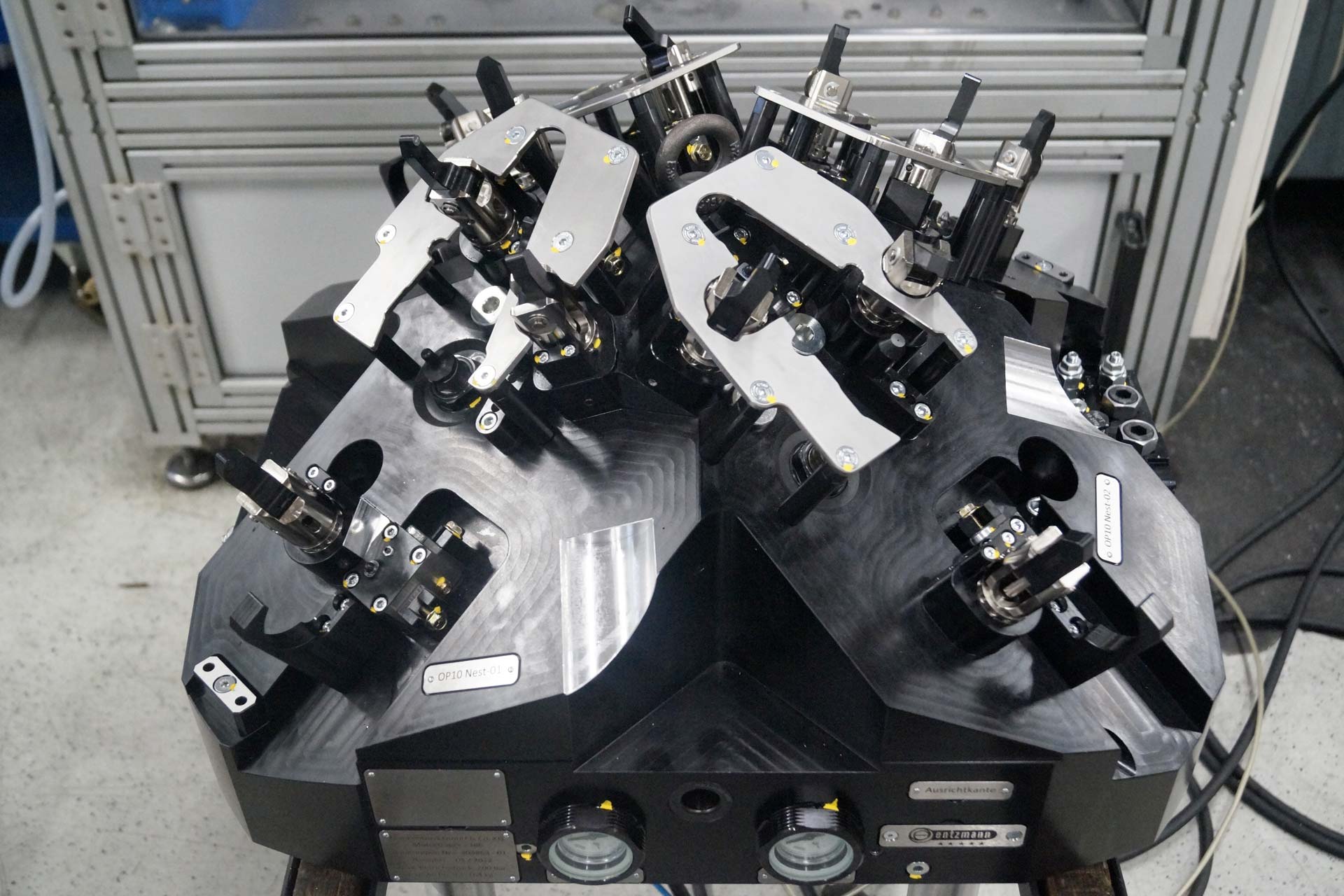

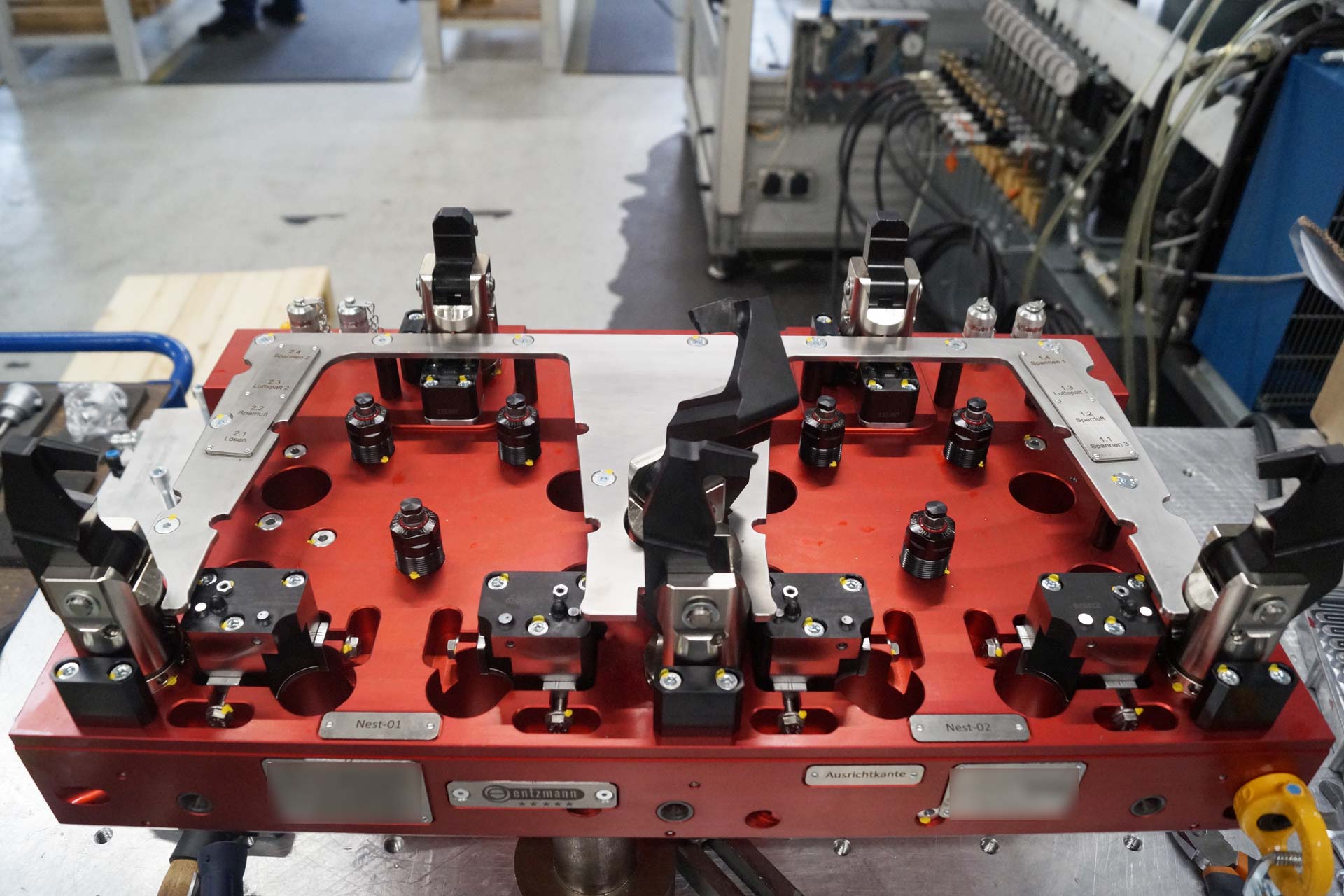

With decades of experience in clamping systems and custom fixture design, we are your expert partner for all clamping requirements. Every single fixture – whether mechanical, pneumatic, hydraulic, electric, or dimension-specific – is designed and manufactured individually, precisely, and safely using modern production methods right here at our facility in the Ostalb region.

We are the fixture specialists with strength, drive, and vision!

Our fixture designs include clamping systems for housings, oil pans, machine tools, and much more. Our focus is on delivering high-performance, custom fixtures tailored to your specific needs. In addition, our services include personalized maintenance, upgrades, optimization, and repair of clamping fixtures – always with direct and personal contact.

Our goal is to provide perfect, high-quality clamping fixtures that enable you to produce successfully and with maximum process reliability. We emphasize cost-effective design solutions based on customer requirements. Each fixture is optimized for space utilization and workpiece clamping position, ensuring you receive a powerful and dependable product. We place great value on ergonomic and user-friendly design. With our clamping fixtures, workpieces can be securely positioned, clamped, and precisely machined on your CNC equipment.

Clamping Fixtures for Maximum Precision and Efficiency in Manufacturing

What are Clamping Fixtures and why are they important?

Clamping fixtures are an essential component of modern manufacturing technologies.

They ensure the secure positioning of workpieces during machining—whether on a CNC machine, milling machine, or lathe. As specialists in workpiece clamping, Frank Entzmann GmbH offers a wide range of high-quality clamping fixtures tailored to our customers’ individual needs.Whether hydraulic, mechanical, pneumatic, or electronic clamping systems – we provide innovative solutions that enhance the efficiency and precision of your production.

Clamping fixtures play a central role in workpiece holding. They ensure that workpieces remain securely and precisely positioned throughout the machining process. This is essential to avoid errors, vibrations, and inaccuracies that could compromise the quality of the final product.

Clamping fixtures are used across a wide range of machining centers and equipment, including:

- CNC-machines: For precise and repeatable machining.

- Milling machines: For producing complex contours and shapes.

- Lathes: For machining rotationally symmetrical parts.

Choosing the right clamping fixture is critical to optimizing manufacturing processes. Depending on the application, hydraulic, mechanical, or pneumatic clamping systems can be used, each offering specific advantages.

Clamping Fixtures for maximum Precision and Efficiency in Manufacturing

Frank Entzmann GmbH offers a wide range of clamping fixtures that can be tailored to your specific requirements. Our product lineup includes:

1. Hydraulic Clamping Fixtures

Hydraulic clamping systems are known for their exceptional clamping force and precision. They operate using hydraulic oil to power the clamping mechanism and are ideal for demanding applications requiring high force.

Advantages of hydraulic clamping fixtures:

- High clamping force and repeatability

- Ideal for complex CNC machining processes

- Automated clamping for increased efficiency

- Adaptable for large workpieces and high production volumes.

Hydraulic fixtures are commonly used in machining centers, especially in high-volume production and demanding milling or turning operations.

2. Mechanical Clamping Fixtures

Mechanical clamping fixtures are a proven solution for many manufacturing applications. Operating without external energy sources, they are particularly low-maintenance and cost-effective. These systems are widely used in smaller production facilities or for simpler tasks.

Advantages of mechanical clamping fixtures:

- Cost-effective and durable

- No external power source required

- Easy to operate and maintain

- Ideal for manual machining applications

Mechanical clamping fixtures are well-suited for milling machines, lathes, and other manual or semi-automated machining processes.

3. Pneumatic Clamping Fixtures

Pneumatic clamping systems use compressed air to secure the workpieces. They provide a fast, flexible clamping solution, especially valued in automated production environments. These systems enable high processing speed and easy integration.

Advantages of pneumatic clamping fixtures:

- Quick clamping and unclamping cycles

- Ideal for automated production lines

- Energy-efficient and easily integrated

- High flexibility for varying workpiece sizes

Pneumatic fixtures are an excellent choice for modern machining centers where speed and adaptability are key.

4. Electronic Clamping Fixtures

Electronic clamping fixtures represent one of the most advanced solutions in clamping technology. Using sensors and intelligent control systems, they monitor and adjust clamping force and positioning in real time. This offers maximum control and automation, making them ideal for Industry 4.0 environments.

Advantages of electronic clamping fixtures:

- Real-time monitoring of clamping force and workpiece position

- Automatic adjustment to varying workpiece parameters

- Seamless integration into digital manufacturing and monitoring systems

- High precision and process reliability for demanding applications

These fixtures are particularly suited for modern CNC machines and machining centers, especially in industries requiring top-tier precision and control, such as automotive or medical technology.

Clamping Fixtures for CNC Machines and Machining Centers

The Process: From Consultation to Commissioning

CNC machines and machining centers demand the highest levels of precision and repeatability. Clamping fixtures play a crucial role in this process, forming the foundation for every machining operation. Frank Entzmann GmbH designs clamping systems specifically tailored to meet the requirements of CNC machines and machining centers.

Why Are Custom Clamping Fixtures So Important?

Every CNC machine and machining center comes with its own unique set of demands. Factors such as workpiece size, material, machining complexity, and production volume all influence the choice of the optimal clamping fixture. Our experts thoroughly analyze your specific requirements and develop tailored solutions that are perfectly matched to your equipment and processes.

Advantages of Our CNC Clamping Fixtures:

- Precise workpiece positioning for maximum machining quality

- Reduced setup times and increased machine uptime

- Optimized cutting parameters for peak efficiency

- Seamless integration into existing production workflows

At Frank Entzmann GmbH, we provide everything from a single source. Our holistic approach ensures that your clamping fixtures are perfectly tailored to your needs – from the initial consultation to final handover.

1. Consultation and Concept Development

Our team offers comprehensive consultation and develops a customized clamping concept designed specifically for your workpieces, machines, and production goals. We analyze all relevant parameters such as clamping areas, support points, tool lengths, and movement paths.

2. Design and Manufacturing

Based on the developed concept, we handle the complete design and manufacturing of the clamping fixtures. Our state-of-the-art production facilities guarantee the highest precision and quality.

3. Commissioning and Training

After manufacturing, we take care of the installation of the clamping fixtures directly on your machine. Our on-site service ensures that your employees are fully trained in the proper handling of the fixtures, ensuring a smooth start-up.

4. Maintenance and Support

Even after handover, we continue to support you with our comprehensive maintenance and repair services. This ensures that your clamping fixtures always operate at peak performance.

Why entzmann?

As a Leading Manufacturer of Clamping Fixtures, we offer you:

- Custom Solutions: Each project is tailored specifically to your requirements.

- Experience and Expertise: Decades of experience in clamping technology and workpiece holding.

- Top Quality: Precision, reliability, and durability are our trademarks.

- Comprehensive Service: From consultation and design to maintenance – everything from a single source

Our clamping fixtures are used in various industries, including mechanical engineering, the automotive industry, aerospace, and medical technology.

Conclusion: Clamping Fixtures for Every Requirement

Frank Entzmann GmbH is your partner for high-quality clamping fixtures that optimize your manufacturing processes and enhance the quality of your products. Whether hydraulic, mechanical, or pneumatic clamping systems, we provide customized solutions perfectly matched to your needs.

Contact us today and let our experts guide you. Together, we’ll develop a clamping solution that takes your production to the next level – precise, efficient, and reliable. Trust Frank Entzmann GmbH, your expert in clamping technology and workpiece holding.