Clamping Technology 4.0 & Fixture Construction, Our Passion

Connected Communication Between Fixture and CNC Machine Perfected

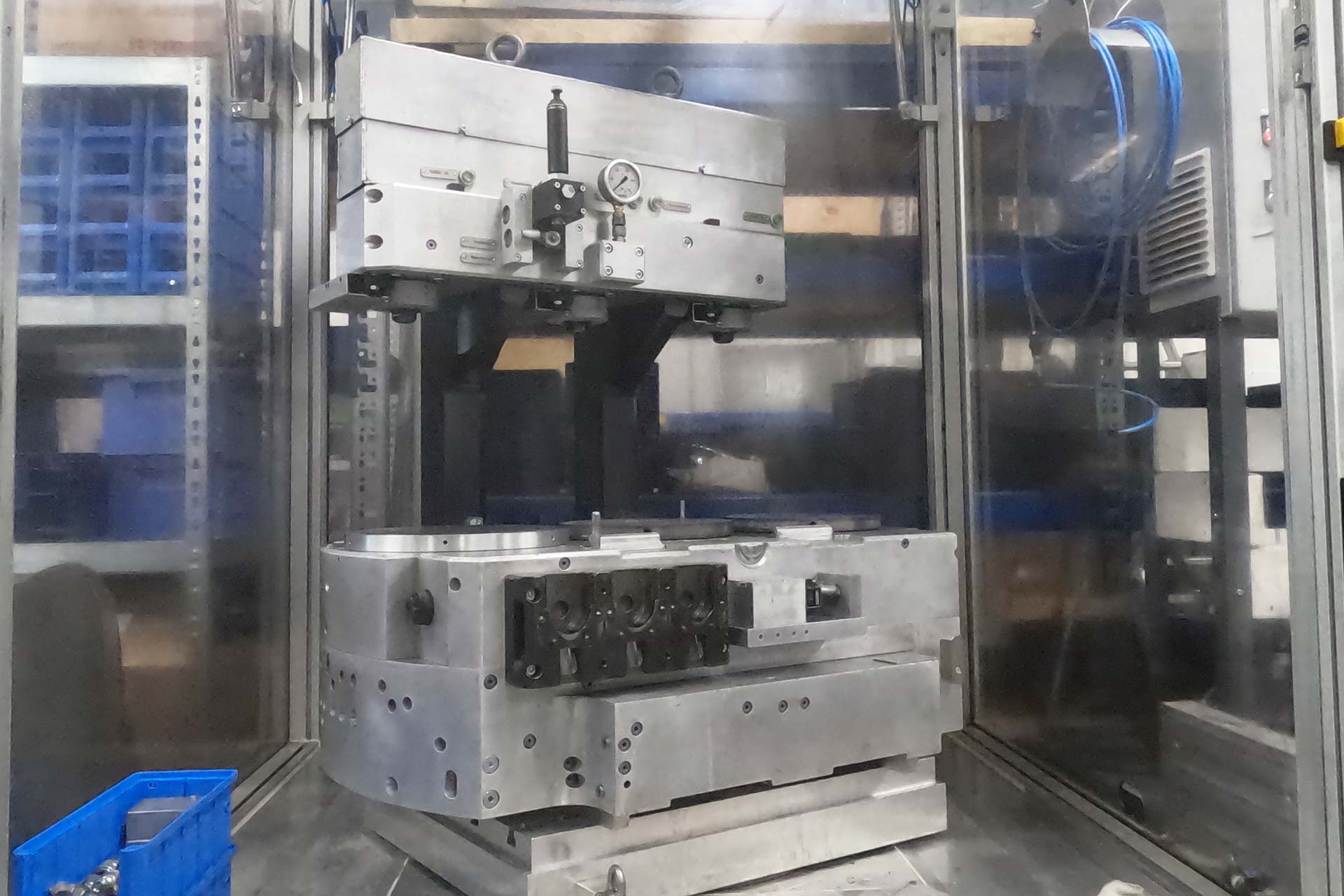

We have revolutionized process reliability in fixture construction within the tool and machine building industry! With our patented electronic transmission and reception unit, we can guarantee process reliability during the workpiece machining process. Depending on the individual application, specific clamping fixtures are required. At entzmann, based in Böbingen an der Rems, we design and manufacture custom clamping solutions of the highest quality – from development to personalized delivery.

We know what we need to deliver to our customers! Intelligent clamping technology & connected fixture construction are our passion.

Tailored, Customized Clamping Concept

As a certified company, we offer you technically robust solutions tailored to the specific application, providing real value to you as our customer. Regardless of the workpiece or machining machine, we will create a suitable clamping concept for you. Whether pneumatic, hydraulic, or electromechanical operation – our manufacturing program leaves nothing to be desired.

No matter what specific clamping requirements you have, our wide range of products, technical expertise, and our own specially developed clamping elements offer you a broad spectrum of optimal solutions for your clamping situation. All under one roof, with sustainable service and always personal contact. entzmann quality guarantees you expertise, dynamism, and innovation.

To prevent disruptions and failures, we also offer our customers a variety of process monitoring and control measures. Machine downtime is minimized, ensuring high process reliability.

High Process Reliability

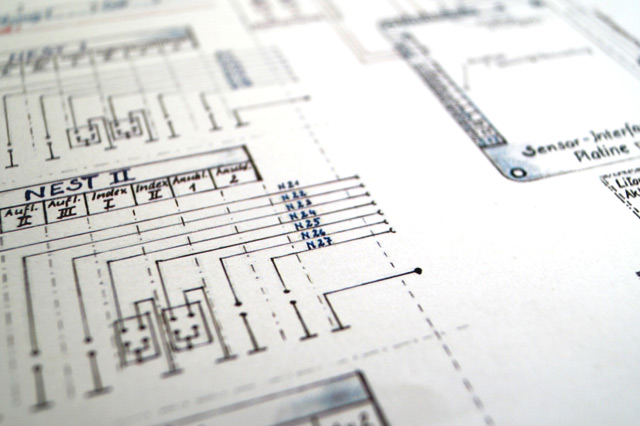

Our clamping fixtures ensure process reliability. This is significantly enhanced by our new and specially developed monitoring system. A sophisticated control device checks all process-relevant parameters before machining begins. This includes workpiece count, supports and position checks, clamping pressure, and much more. The machine is only authorized to start once all parameters are met.

We provide a variety of intelligent process monitoring and control measures. entzmann enables optimal information exchange between the machining machine and the clamping fixture. Frank Entzmann GmbH is the only manufacturer capable of equipping all fixtures with a transmission and reception unit. This guarantees modern machine-to-machine or fixture-to-machine communication.

Our fixtures can be easily integrated into the real-time monitoring of any existing IT system. This guarantees you very high process reliability for your machining machine. Disruptions and failures are effectively avoided. Error messages are logged, and the machine can only restart once the issue is resolved. This ensures safety and protects against unwanted production defects, tool breakages, and repair costs. We would be happy to explain the technical details in a personal meeting.